Evolution of Maintenance service

-

Reactive On-call service

- Compliance inspections

- On-call repairs

- Basic and Routine maintenance

1st Gen

-

Preventive and Corrective Service

- Planned preventive maintenance

- Workforce multi-skilling and team working

2nd Gen

-

IoT powered maintenance service

- Real-time data collection through IoT

- Predictive and prescriptive maintenance

3rd Gen

Why Remote Machine Monitoring?

• Preventive maintenance led to either over-maintenance resulting in higher costs or under-maintenance resulting in breakdowns and downtime.

• IoT has become a key enabler in predicting breakdowns and keep them healthier and running for longer time.

• The industry is transforming by adopting IoT powered maintenance.

Pratomate’s IoT powered Remote machine monitoring helps

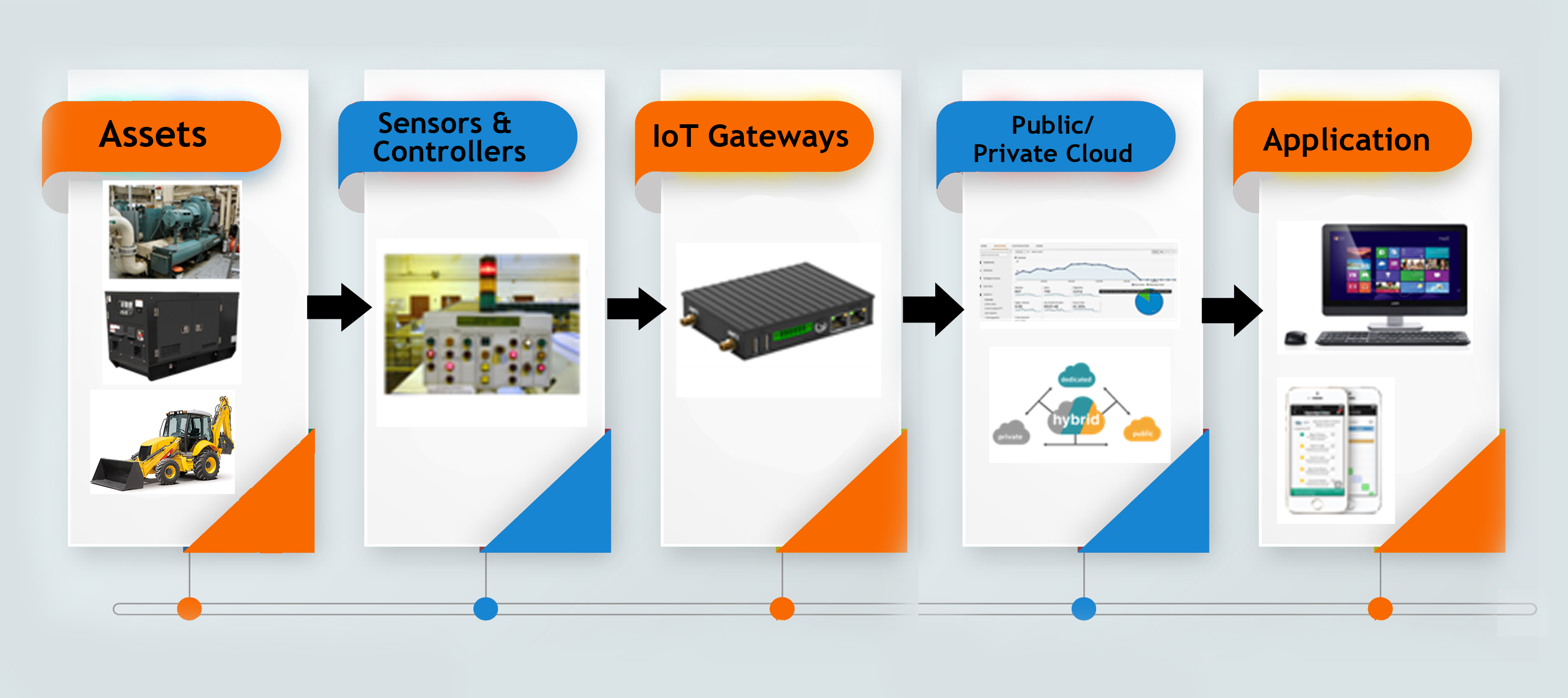

Collect real-time data through controllers, sensors and IoT.

Analyse data to understand threshold limits of operational parameters and breakdown causes

Get insights into machines for healthier and longer operational times

How it works

BENEFITS

Reduces on-site visits by up to 20% through threshold alerts and breakdown causes

Reduces warranty cost by around 39% through warranty management

Helps improve new machine designs to avoid similar breakdowns with help of detailed reports

Case Studies

A leader in Backhoe loader machines achieved excellence in machine designs with our solution

Our solution helped a manufacturer of Diesel Gensets and Chillers improve service speed with problem element traceability